Rotomolding, also known as rotational molding, is a production procedure wherein a hollow item is generated throughout the heating system and rotation of your polymer material. It is a adaptable manufacturing method that can produce items of various styles, styles, and colours. Several market sectors, from vehicle to medical care, make use of Rotational Molding to produce substantial-good quality products. In the following paragraphs, we are going to go over the skill of Rotomolding and just how it will help form your success.

Style and Materials Choice

The first step in Rotomolding is making a merchandise design and style. This design and style must be made with the production method in your mind, to be sure the merchandise can be created through Rotomolding. It is additionally crucial that you select the suitable resources for your item. The information assortment depends on numerous factors such as the product’s finish use, price, and wanted components. After the design and style is done and components are determined, the method can start.

Fungus Creation

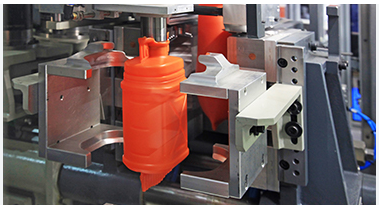

The next step is creating the mold. The mildew for Rotomolding is generally made from aluminum or metallic and is made to be hollow. It is made up of at least two halves which are clamped together throughout the molding approach. The mildew needs to be made with the product style under consideration so that the done product will be exact and of top quality.

Warming and Molding

As soon as the fungus is ready, the polymer materials is added, and it is heated up. The home heating method helps make the material gentle and flexible, therefore it can evenly cover the inside of the fungus. When the suitable temperatures is achieved, the fungus is rotated on several axes, causing the material to disperse and follow the mold’s walls. The process continues before the materials has cooled, and the item is complete.

Completing and Top quality Manage

Right after the fungus is established, the plastic product is then taken out and cleaned up. Additional features like color, peel off stickers, or logos may also be included in this phase. Good quality control actions must be carried out, making certain the last merchandise is perfectly up to company standards.

Environment Advantages

Rotomolding is an environmentally friendly producing procedure mainly because it produces significantly less waste, and the resources utilized can easily grow to be recyclable. Rotational molding method also helps save power, as merely the fungus is warmed rather than the total oven, and is particularly designed to be power efficient, more lowering emissions and energy ingestion.

In short:

In In a nutshell, the art of Rotomolding can be a method that has established numerous products throughout the years, including car elements, toys and games, and also home items like rubbish cans. Prototyping, substance assortment, mildew design and high quality manage are important aspects of the Rotomolding procedure. With its accommodating design and style choices, you may form ensuring your success through Rotomolding. In addition, with eco-friendly rewards, it is an best producing method for companies trying to find eco friendly, cost-effective producing alternatives.